What Is an RF Coaxial Cable and How Do You Choose the Right One? Structure, Performance, and selection Guide

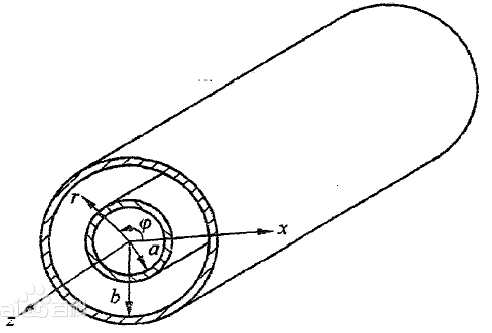

An RF coaxial cable is a guided wave transmission system made of two coaxial cylindrical conductors, with air or a high-frequency dielectric material filling the space between them. Designed as a broadband microwave transmission line, it plays a vital role in communication, broadcasting, and audio-visual applications.

Although coaxial cables are common, the differences in their materials, construction, and performance can be complex—especially for those without specialized RF or microwave knowledge. Without a clear understanding of these factors, choosing the right RF coaxial cable can be challenging, leading to mismatched products and unsatisfactory performance.

What Makes RF Coaxial Cables Unique?

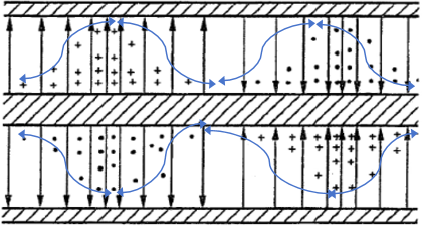

A coaxial cable is a shielded, non-dispersive transmission line. Theoretically, its lower cutoff frequency is zero, meaning it can carry very low frequencies as well as high-frequency signals. It consists of two conductors—an inner conductor and an outer conductor—separated by a dielectric material.

In most cases, the outer conductor is grounded. This keeps the electromagnetic field entirely contained between the conductors, resulting in minimal radiation loss and excellent resistance to external interference. Compared to two-wire lines, an RF coaxial cable supports a wider operating frequency range, even in centimeter-wave applications.

Power Capacity and Transmission Loss

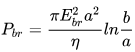

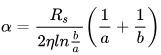

The performance of an RF coaxial cable depends heavily on its dimensions:

l Maximum Power Capacity occurs when the ratio of the outer to inner conductor diameters (b/a) is about 1.649. For an air-filled cable, this corresponds to a characteristic impedance of about 30 Ω.

l Minimum Transmission Loss happens when b/a = 3.6, giving a characteristic impedance of roughly 76.85 Ω for an air-filled cable.

The Four Core Components of an RF Coaxial Cable

Every coaxial cable—regardless of type—shares the same four main parts:

1. Central Conductor

This forms the core pathway for signal transmission. Materials like high-purity copper, silver-plated copper, or copper-clad aluminum are common.

l Thicker conductors allow for stronger signal transmission and lower loss, making them ideal for long-distance use.

l Large cables often use copper tubes to reduce weight and cost.

2. Insulation Layer

This layer maintains the spacing between the conductor and the shield, supports the cable’s structure, and determines the characteristic impedance. Common materials include:

l PVC – Low cost, suitable for low-voltage applications.

l XLPE – Good heat resistance, widely used in medium/high-voltage cables.

l Fluoroplastics (PTFE, PFA) – Extreme temperature resistance and chemical stability.

l Physically Foamed PE – Low dielectric constant for faster signal transmission.

3. Shielding Layer

The shield protects against electromagnetic interference (EMI) and radio frequency interference (RFI), while also preventing signal leakage. Shield types include:

l Single-layer copper braid

l Copper braid plus aluminum foil

l Multi-layer copper mesh with foil

l Threaded copper tube wrapping

4. Outer Sheath

The sheath defends against mechanical damage, moisture, corrosion, and UV exposure.

l Common materials: PVC, PE

l High-performance materials: PTFE for extreme environments

Choosing the Right RF Coaxial Cable

When selecting an RF coaxial cable, consider:

l Frequency range – Ensure the cable supports your operating band.

l Power capacity – Match the conductor size and impedance to your power needs.

l Loss performance – For long distances, prioritize low-loss designs.

l Environmental resistance – Use materials suited for temperature, moisture, and UV conditions.

An RF coaxial cable is more than just a wire—it’s a carefully engineered system where materials, geometry, and shielding all work together to deliver optimal signal transmission. By understanding its structure and specifications, you can select the right cable for reliable, high-performance connections.

Comments

Post a Comment